Line Stopping Service

Line Stopping Service

Line stopping is a system designed to stop flow through a pipeline while equipment repairs, or maintenance work is being carried out.

The line stopping method (also known as flow stopping) is a mechanical process used to temporarily isolate a section of a live pipeline for repairs or modifications without shutting down the entire system. This technique is essential for critical services like water, gas, and oil, where a total shutdown would be costly or disruptive.

Gallery

Types of Line Stopping

Mechanical Plugs / Pivoting Head Line Stop

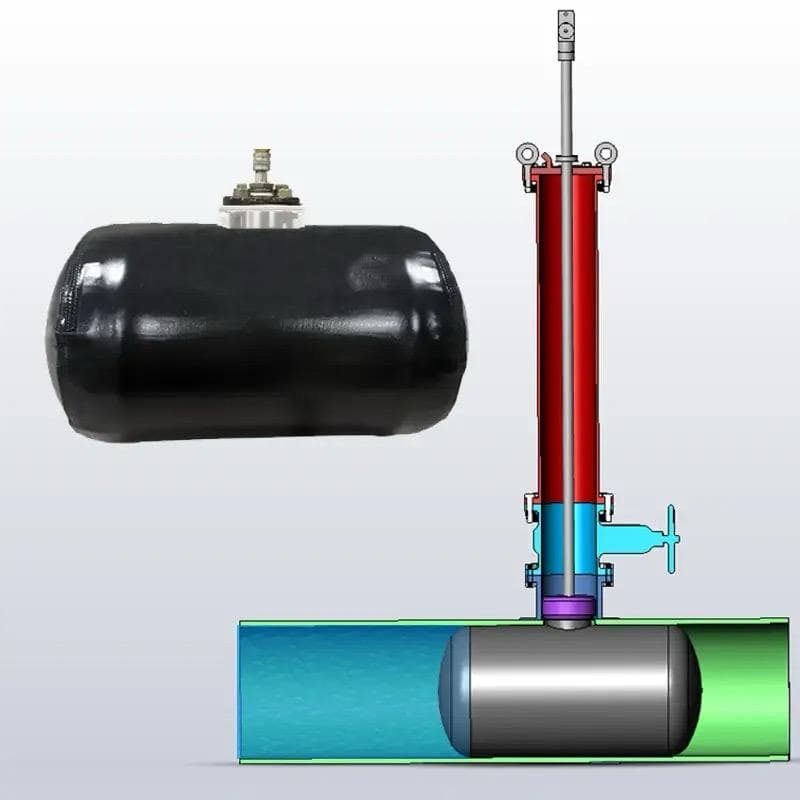

A specialist plugging head is inserted into the line through a fitting and the flow is stopped or redirected through bypass piping. A Line Stop starts out the same way as does a Hot Tap. Once the cut is made, the valve is closed the hot tap machine is removed from the line, and a line stop machine is bolted into place. The line stop machine is operated, to push the plugging head (mechanical head) down into the pipe, and form a stop, thus stopping the flow in the pipe.

Inflatable line stop / Bag line stop

Inflatable line stop (also known as an inflatable pipe plug or balloon plug) is a flexible, temporary sealing device inserted into a pipe or conduit and then inflated to create a watertight or airtight seal. This allows workers to isolate a section of a pipeline for maintenance, repairs, or testing without needing to drain or shut down the entire system.